|

|

|

|

|

|

|

|

Wing Spar Glue-Up |

Wing Spars |

Aileron Glue-Up |

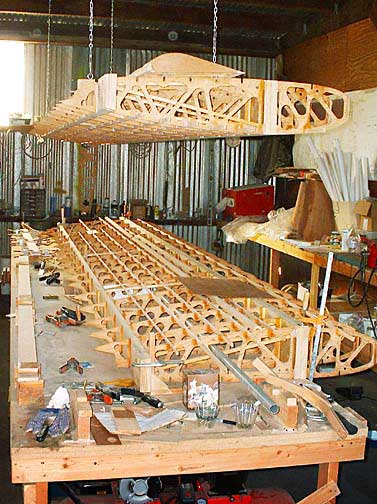

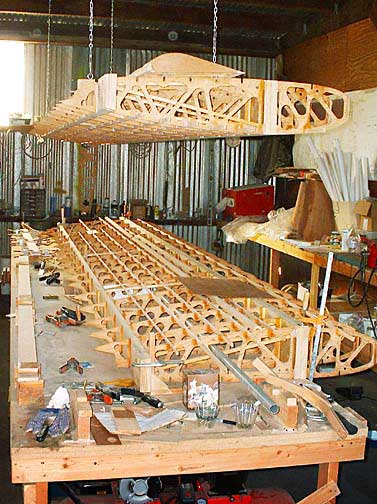

Complete Wing Skeleton With Flap Mounted |

Flap Actuator |

Skinned Flap Mounted On Right Wing |

Detail of Nose Ribs With Extra Strips Glued In Place for LE |

Detail - Flap Actuator arm and Torque Tube. Bottom Skin ON |

Detail of Flap Hinge from Inside of Flap |

Detail for Flap Hinge from Front of Flap |

|

|

|

|