Chapter #9, Rear Landing

Gear (needs legs, axles, wheels, brakes, brake lines and covers

built)

ESTIMATED COST OF ASSEMBLY: $2000.00

Includes Parts, Spring gear legs, machine work, but not wheels brakes

or tires.

MODIFICATIONS: * Gear now

properly locks in the down AND the up position.

*Gear UNLOCK mechanism... Look

at the photos: The unlock cable is pulled and it actuates a cam that

"pushes" the locking hinge out of the locked (overcenter) position.

I ran the cable down to the lower part of the assembly (near the keel)

to allow the cable to retain the same working length for unlocking both

gear up and gear down.

*I also used machined phenolic bushings

in place of the nylon runners inside the bearing plates.

NOTES ON PLANS: The plans

are a little confusing with respect to the up and down positions.

The confusion comes from the evolution of the plane as larger engines were

added. As the engine weight grew, the step, and the landing gear

position moved aft. On the landing gear this was accomplished by

changing the rotational angle of the main gear tube, rotating it rearwards.

I ended up working it all out on a CAD program to get things to be what

I hope will be right. The down position is correct, I am awaiting

the mounting of my wings to confirm that the rear tires do not interfere

with the wing strut. I should know this by Summer 2003, (Note:later

with wings attached the gear did work out to the right positions)

There are three microswitches on the assembly indicating gear up &

gear locked (not visible), the gear down switch is visible on top of the

assembly.

NOTES ON ASSEMBLY: Keep

track of assembly and dissassembly order, it can get confusing sliding

the various objects over the tubes and getting them lined up correctly

as you put it all together. I painted everything and this caused

too much friction on the bearing plates, I ended up sanding a bunch of

the paint off. Don't build to tight tollerances if you plan to paint

THINGS I WOULD DO DIFFERENTLY NEXT

TIME: I later moved the position of the barke lines into the

interior section of the hull see chapter #15 for

details. If doing it all over agoin I would also use wider rings

(outboard) that hold the tube in place and find some real wiper seals to

seal the tube at the wet well. This would be easy to do and would

eliminate the "weeping" of water into the hull during water operations.

|

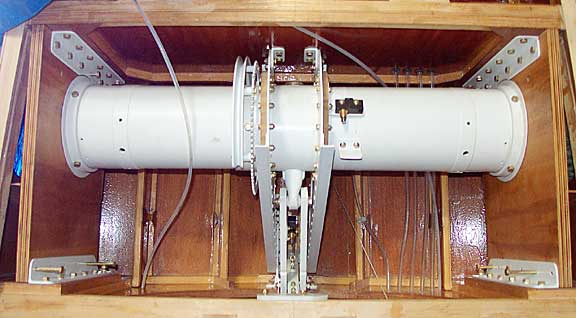

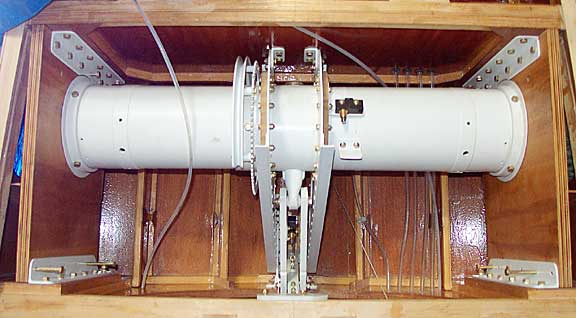

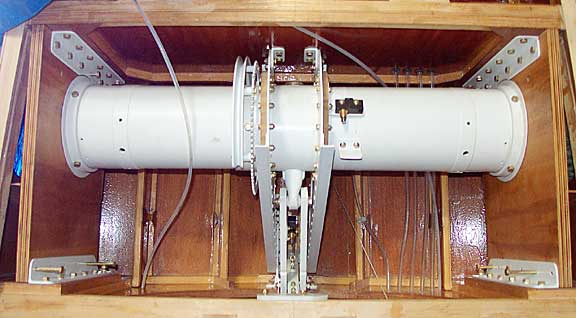

Seen here is the RLG assembly from

a birds-eye view. The locking pin shown was replaced with a machined

2024-T3 Aluminum pin.

|

Lock Plate Bearing Parts

|

Rear Box Parts

|

Gear Well (incomplete)

|

Side View

|

Gear Half way Articulated

|

Unlock Cam, Cable

|

Unlock Cam

|

Lock Spring Pulley @ Keel

|